A filter press is the best way to solve your wastewater problems, it can save money and maximize returns.

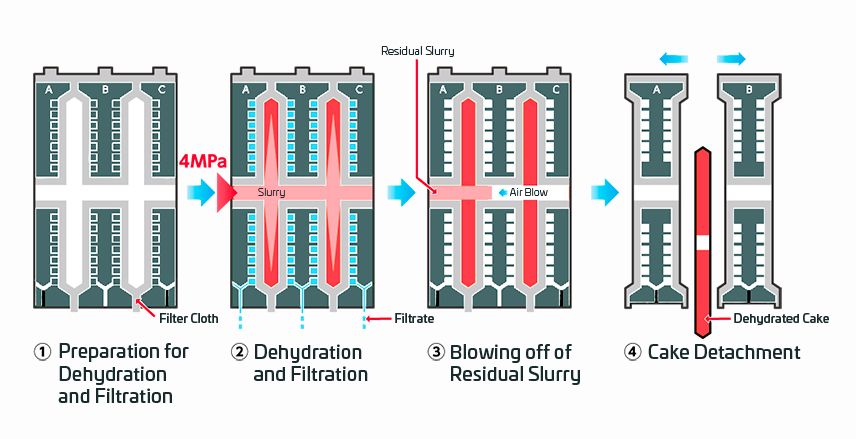

The filterpress (or filter press) is an industrial machine used to dewater sludge by means of solid-liquid separation processes.

In other words, filter pressing is a system for the volumetric reduction of liquid substances that have suspended solids inside..

Press filters are now used in different industrial sectors: for the dewatering of sludge deriving from wastewater purification processes, civil and industrial, and in many chemical / pharmaceutical and mining processes.

In the future, the market demands for the modern filtration industry will become more and more subtle in separation, especially with regard to material recycling, energy saving and green technology. To meet the increasing demands for a higher degree of dewatering from difficult to filter materials, very high pressure filters are required. Therefore, the tendency to increase the pressure for the automatic filter press will continue to develop in the future.

Mining Processes: Gold, Zinc, Copper, Tin

Food Processes: Pomace pressing

Pharmaceutical Processes: Antibiotic

Inert: Earth quarries

Lees squeezing (Marc)

A simple and effective solution for all processes that involve the separation of the liquid part from the suspended solids. The plate filter presses allow the recovery of the liquid part that the lees still contain, at the same time obtaining solid panels rich in materials that can be used by the industries that process the cellar by-products.

CHEMICAL SECTOR

Filter press for the chemical sector

This sector provides a multitude of applications, the filter press is used in the refining processes of dyes, catalysts, pigments, etc. ... trova anche applicazione nella purificazione di carboni, fibre e molto altro.

The filter press used for the chemical sector uses chambered plates, the high filtration standards allow the treatment of large varieties of products deriving from the chemical industry. The filter press in the chemical sector is able to obtain solid residues with very low residual humidity values and solutions to be recovered, this happens in a single operation.

The filter press in the chemical sector can be used for the following treatments:

Filter press for the extraction of silicates from siliceous sands,

Filter press for the purification of organic and inorganic catalysts,

The stearates are refined with chambered chamber filter presses,

The washing of solutions and subsequent filtration with a filter press of organic and inorganic acids,

Recovery of aluminum hydroxides with membrane or chambered plate filter press,

Filter press for the recovery of refinery metals,

Filter press with special plates and filter cloths for precious metal recovery at high temperature,

Filter press for the refining of carbonate and calcium sulphate whiteners,

The recovery of stearates and dyes in the chemical sector takes place through our filter presses,

Filter press for cleaning polyamide chemical fibers.